Cruise Ship Propeller Cost

Propellers commonly called screws are an integral component of any cruise ship and are used to provide both forward and reverse momentum.

Cruise ship propeller cost. The price depends on the size material and amount of work required. PROPELLER RECONDITIONING and RE-PITCHING SERVICE. Daphne Osborne CEO of MSC Cruises also noted Malcom Young was fired on Friday one week after the accident when the ship reached Durban.

The trials involved eight 17700 dwt vessels six of which were fitted with standard rudders and two with Energopac. Each propeller was operated using separate engines. Osborne said the firing had nothing to do with the accident.

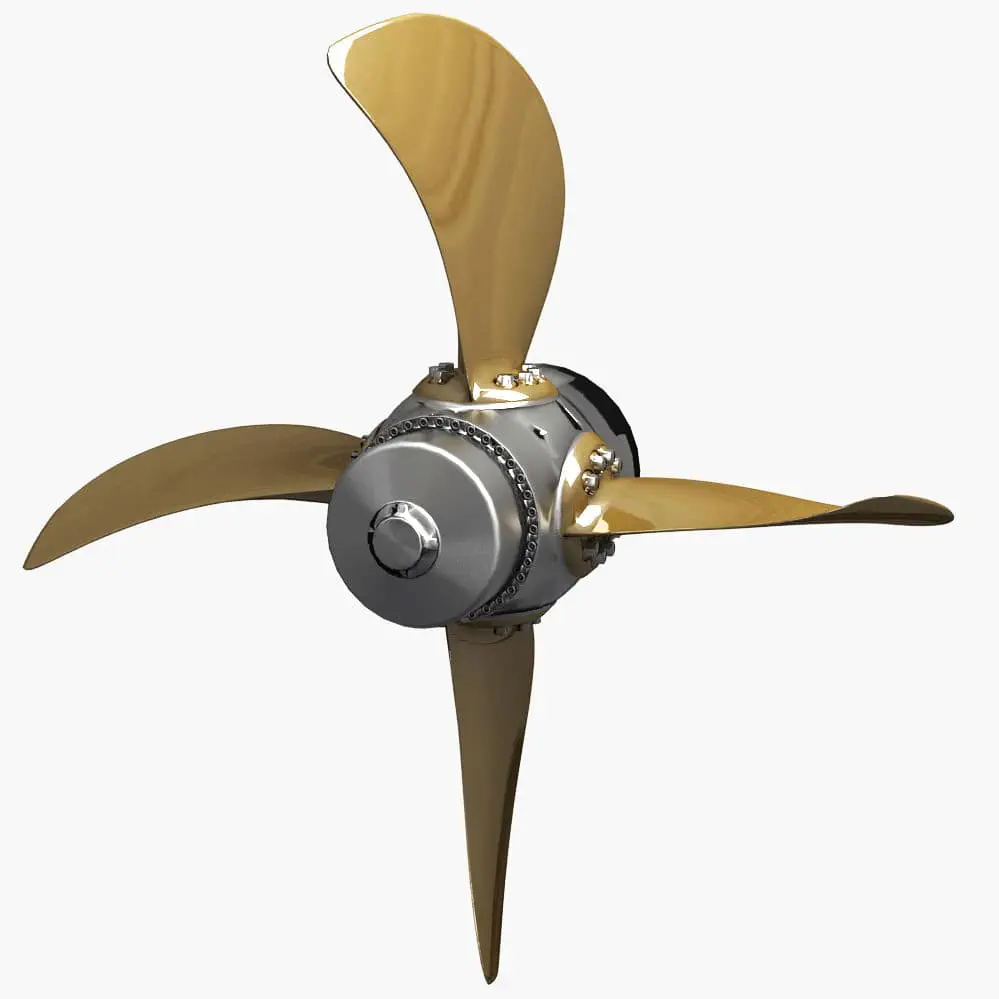

The cruise industry is a fast-growing category in the leisure travel market and cruise performance monitoring for your. The high performance of the thruster is achieved by a unique hybrid cooling of the propulsion motor combining a direct cooling to the surrounding sea water and an active air cooling system. The most fun fact of all in this category is the berth price of one of the worlds most expensive big cruise ships - the most famous Cunard liner RMS Queen Mary 2 2004-built with a berth cost of over the USD 300000 - the industrys highest-ever.

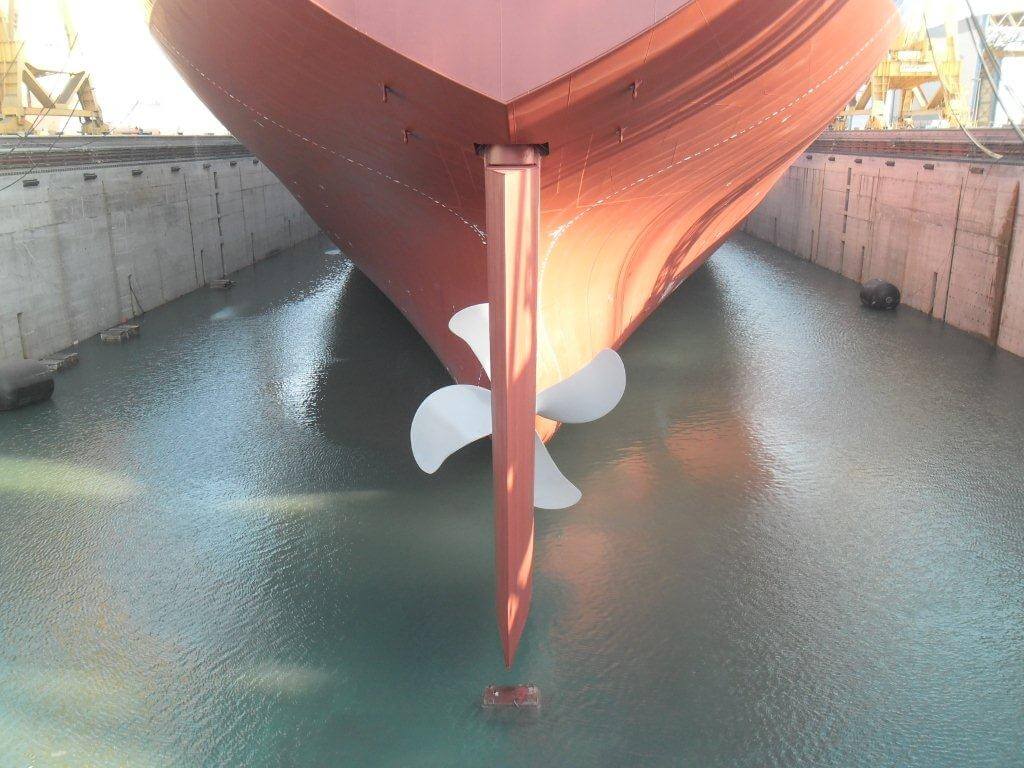

At the shipowners request Thordon Bearings the market leader in water lubricated bearing. The difference between the nominal. All cruise ships rely on propellers to push them through water.

In this aspect the hull form of. There were three propellers in this ship weighing 38 tons each. Cruise industry began in 1844 when ships were propelled by steam engines performing the driving of propellers by using steam as working fluid.

The pulling propeller eats from the homogenous field of water. Seawise Giant was the longest ship ever built. In reality since the propeller is attached to a shaft it will not actually move forward but instead propel the ship forward.